My splice power cord has never caused me problems. However, based on my experience, it is something I can do when I’m in a pinch and cannot find an intact cable. The NEC says we should not splice an electrical cord. It can be done by simply connecting the wires and insulating them. Splicing extension cords is a quick way to repair a cord that has been cut. How Do You Repair an Extension Cord that has Been Cut? You can try the method above for mending a cut power cord.Īlternatively, if your extension cable damage is on the plug part, you can splice plug and replace it with a new part.īut if your problem is a melted extension cord, I’m afraid you need a whole new one. Yes! You can repair a damaged extension cord as long as its wires are usable. Finally, put the heat-shrink tube over the connected wires and heat-blow it.Then, wait at least four hours for the liquid tape to dry based on its instructions.During the second coating, apply sealant along the edges where the outer jacket is removed.Wait 10 minutes for the coating to dry before applying another coat.

Inspect the wire to verify you haven’t missed any areas. Stir the sealant thoroughly before applying the first coating to each connected wire.Here is the extension cord splice kit you must have to adequately connect the wires. If you want to fix a cut extension cord, here are the tools and guide you can follow. However, you should do it properly to eliminate the risk of electrocution. The repair process is very simple, consisting of connecting the extension cord wiring. Instead, just repair extension cord so you can use it again. In such cases, you do not need to replace it immediately. When wrapping extension cord, you may notice some visible cracks on it caused by animal bites or contact against sharp objects. But they can’t protect the entire length of the cord, which can easily get damaged. They are both effective materials for insulation.

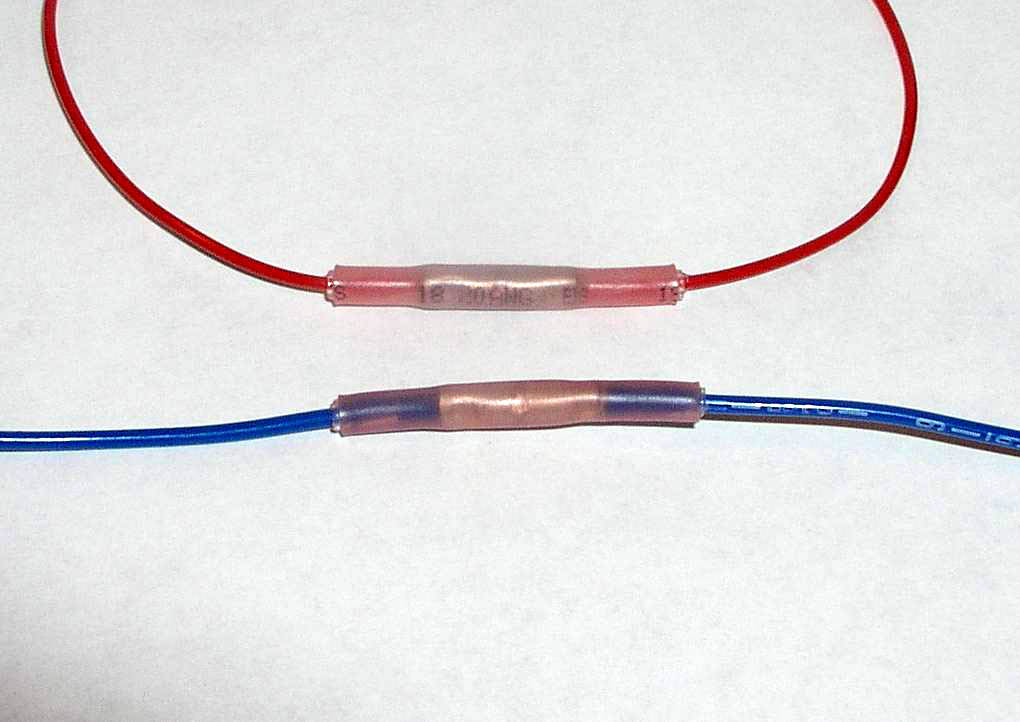

Some butt splice connectors have vinyl insulation, whereas others have nylon insulation. Insulation is the nonconductive material on the outside of a connector. All butt splice connectors have insulation. Utilizing extension cord connectors is good for the connection between your device and outlet. You should consider the insulation when choosing butt splice connectors. Remove the Insulation Cover and Strip the Wires Step-By-Step to Splice an Extension Cord.

#Butt splice verification

our company established an independent UL laboratory in 2015, which enables KF to obtain timely and effective data, and in turn, delivering satisfactory results in regards to both the technical verification in product development and the regular quality inspection of manufactured Vinyl-Insulated Butt Splice Connectors for sale. In this way, the reliability, safety, and appearance of our electrical connectors is greatly improved. Meanwhile, the advanced production and inspection equipment contribute to the standardized and efficient manufacturing processes KF.The imported automation equipment ensures that every process is consistent and perfect Vinyl-Insulated Butt Splice Connectors. is China Vinyl-Insulated Butt Splice Connectors Manufacturers and Vinyl-Insulated Butt Splice Connectors factory, we has continuously introduced automation equipment to improve its production processes. Modern industrial production, automation, and intellectualization can effectively guarantee our efficiency and quality.

Vinyl-Insulated Butt Splice Connectors Manufacturers

0 kommentar(er)

0 kommentar(er)